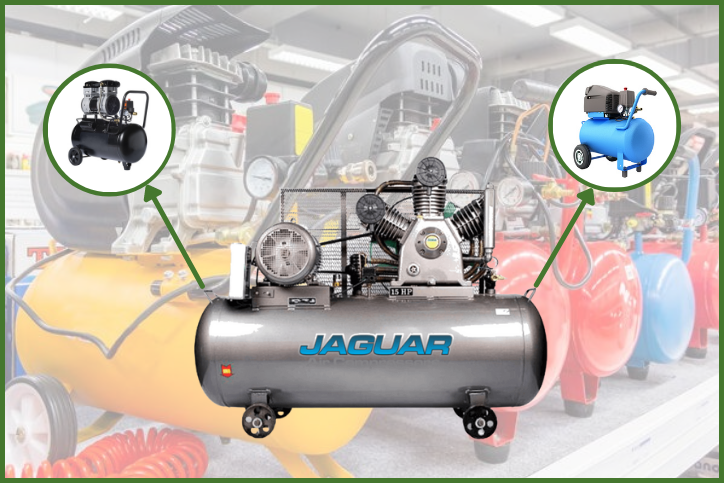

The main objective of this article is to explain the air or gas compressors and different types of air compressors. Compressors are essential in almost all industries.

What is a Compressor?

A mechanically operated machine that rises the fluid pressure by reducing its volume is called a Compressor. If the compressor uses gas as a working fluid, it is called a gas compressor. While if the air uses as a working fluid, it is called an air compressor. Naturally, in a compressor, the compressed air gas raises the temperature.

An air compressor is also a specific kind of machine that operates with compressed air aid and is used in different industries. The air compressor has gained worldwide recognition after its discovery in the year 1875.

With the help of the air compressors, people could save their time and money in almost every work. It was even found that these devices had a great impact on the lives of the people. A lot of work was taken up by the people who were able to reduce their work, and this has led to a major increase in the productivity of the people and their performance levels. This is the main reason why the demand for compressors has gone up drastically.

The working of a compressor is like a pump. But their work is a little bit different. But both pump and compressor mechanical devices increase the pressure of the fluid.

How Does A Compressor Work?

The basic working principle of gas or air compressor can be easily understood. It works by changing the volume of the gas or air. It uses a piston or diffuser to increase the pressure of the working fluid. When the working fluid enters into a diffuser which changes the speed of the fluid into pressure energy.

In this way, a compressor compresses the gas or air. After the compression process, the compressed air is transformed into a storage tank. Many industries have used compressors to increase production, which has led to the development of many new industries.

Nowadays, many companies manufacture and supply air compressors to different industries. The manufacturing of these machines was initially done using wood, but now many modern techniques and materials are being used to manufacture them. Many countries are using air compressors to their advantage. They are making use of these machines to save their precious time, energy, and money.

Types of Air Compressor

The most famous types of air compressors are given below in detail.

The air compressor has two main types that are:

- Positive Displacement Compressors

- Dynamic Compressors

These two types are further divided into more different types that are given below.

1) Positive Displacement Air Compressor

It is the most famous type of air compressor. The function of the positive displacement compressor is straightforward.

These compressors reduce the volume of the compression chamber by introducing air into the compression chamber through the suction air. It compresses the air until the air pressure reaches according to the requirements. The compressed air is then blown out of the valve at nominal pressure to provide airflow.

Another definition of a PD compressor, a compressor that works by drawing a distinct amount of gas or air from the inlet of the compressor and then forcibly exiting it from the outlet of the compressor, is called a Positive displacement (PD) compressor.

The positive displacement compressors have the below-given types:

1.1) Reciprocating Compressors

These types of air compressors use a piston or plunger that pushes by a crankshaft. This piston or plunger moves at a constant speed to pull the air in then compresses it. Typically, one drive of the piston sucks the air in the cylinder, and the other drive squeezes it.

The small reciprocating compressors have power from 5 to 30 horsepower that is mostly found in the applications of automobiles and is generally used for intermittent operation.

Large reciprocating compressors are more than 1000 horsepower and are commonly used in petroleum and large industrial applications. In large industries, these are used for applications like chemical plants, industry, oil refineries, and natural gas processing and delivery.

Advantage of Reciprocating Compressors:

- These are easy to maintain

- These are best for applications that need high pressure

- Very highly efficient and flexible

- It has a simple design

Disadvantages of Reciprocating Compressors:

- These compressors produce high noise

- It is a highly vibrating equipment

- It has a large size

1.2) Rotary Screw Compressors

These are the most common types of air compressors used nowadays. In a rotary screw compressor, air sucks into the compressor, closes the openings, and compresses the air with the help of two rotors that rotate continuously and run via the cavity. With each revolution, the air pressure gradually increases until it touches the desired pressure.

The classification of the screw compressors depends on the type of gearbox, the method of cooling, and the stage. These types of air compressors are generally manufactured in dry variety, water, and oil flooded.

The rotary compressor′s efficiency is very dependent on the air dryer. Screw compressors have few components, high efficiency, large capacity, simple structure, voltage spikes, and low vibration and can run at low speed to adjust power.

Advantages:

- These don’t use a piston

- These have higher than piston compressors

- This compressor gets less space for installation

- It has less vibration and types than other types

- It has high reliability

- Highly efficient

- It has a long service life

Disadvantages:

- These have a high cost than other positive displacement compressors

- These also need high maintenance

- High precision

- It needs for special equipment processing

- High service cost

1.3) Ionic Air Compressor

The ionic compressor is also called an ionic liquid piston pump. This is a liquid ionic piston-based hydrogen compressor, not a metal piston like a metal diaphragm piston compressor.

Advantages:

- It doesn’t require a seal and bearings

- It has a long service life

- This type decreases energy consumption

- It requires low maintenance

1.4) Rotary Vane Compressors

The rotary air compressor is another well-known compressor. In this compressor, two asymmetrical rotors (also known as spiral screws) use for the compression of the air.

The rotary vane gas compressor consists of a rotor with a large number of vanes or blades. These blades fix into the radial groove of the rotor—the rotor fixes in a housing with a rounder or more complicated structure.

When the rotor rotates, the vanes move inward and outward of the slot and contact the housing outside the wall. Thus, the rotor blades create a series of maximizing and minimizing volumes. This compressor is the oldest technology of compressor.

These are used for the applications such as tire inflation in tires and wheel shops, dry cleaning and paint pumps, etc.

Advantages:

- It has an easy design

- Highly efficient

- It has a low initial cost

- It has a compact size

- Simple design

Disadvantages:

- It uses for limited applications

- It highly vibrates during the working

- This compressor has a high number of moving components

- Due to many moving parts, it has a high maintenance cost

1.5) Rolling Piston Compressor

The rotary piston of this type of air compressor acts as a separation between the rotor and the blade. This piston pushes the gas towards the fixed vanes. Two of these compressors can fix on the same shaft to decrease noise and vibration and increase capacity. A springless version knows as a swing compressor.

This gas compressor is more efficient than a reciprocating compressor because less space is lost between the piston and the compressor housing. With a given capacity, the volume of the rolling piston compressor reduces between 40% and 50%, and the weight increases. It has fewer vibrations, fewer parts. It is more reliable as compared to the reciprocating compressor.

Advantages:

- It has a low maintenance cost

- It has a low initial cost

- Simple control

Disadvantages:

- It has low efficiency

- It isn’t quiet

- These compressors have low efficiency

1.6) Scroll Compressor

Scroll compressors are also called scroll vacuum pumps or scroll pumps. These types of air compressors use two offset spiral blades to compress or pump to different fluids like air or gases and liquids. The shape of the blade can be a mixed curve or Archimedean spiral.

These types of compressors work smoothly in a lower capacity limit than other types of compressors. It is quieter and more reliable.

Usually, one scroll is rigged, but the other is eccentric and does not rotate, pumping, trapping, or squeezing pockets of the available air between the scrolls.

These are used for the applications such as residential, air conditioners, marine containers, fruit, and food refrigeration, vacuum pumps, and truck transportation, etc.

Advantages:

- It has a low pulsation of gas

- Low weight

- These have a quiet operation

- There is no use of piston

- It has only a few moving components

- It has high durability

Disadvantages:

- It has a low capacity

- These have a high cost

1.7) Diaphragm Compressor

This type of air compressor is a kind of conservative piston compressor. In these compressors, gas or air compression causes when the flexible diaphragm moves, not the intake component.

The forward and backward motion of the diaphragm handles with the help of a crankshaft and a rod mechanism. When there is a need for gas compression then only the compressor box and the membrane makes contact with the gas. The degree of bending and the material of the membrane affect the life of the device.

Silicone or rubber diaphragm compressors can withstand very high deflection depths. Still, due to the low strength of these compressors bounds their use in low-pressure applications and requires replacement if the plastic becomes brittle. These use in many applications like compressed natural gas (CNG) and hydrogen plants.

Read more: Diaphragm Compressor working

Types of Dynamic Air Compressor

Types of dynamic compressors are given below.

2.1) Centrifugal Compressors

The centrifugal compressor includes the most famous air compressor types. It uses a rotatory impeller or a disc in the housing to push the gas or air towards the blades of the impeller. The impeller blades raise the speed of the gas. The diffuser transforms the energy of the gas speed into pressure. After that, the gas is transferred to the desired location.

These compressors are mainly utilized for constant, fixed applications in industries like petrochemical plants, natural gas, chemical plants, and oil refinery processing plants. Its applications range from 100 hp to thousands of hp. With various upgrades, high outlet pressures above 6.9 MPa (1,000 psi) can be achieved.

These kinds of air compressors are widely used in air conditioning systems and large refrigeration.

Advantages:

- It has low weight

- It has an easy designing

- Easy to maintain

- Energy efficient

- These are reliable

Disadvantage:

- Not suitable for high compression applications

- It has choking, stalling, and surging problems

- It produces a limited amount of pressure

2.2) Axial Air Compressors

The axial compressor is a type of dynamic compressor. These are very famous types of air compressors—these are used when compact designs or high flow rates are needed. The axial compressor uses a series of fan-shaped air blades to compress the liquid gradually.

In this type, the wings arrange in pairs, one in a stationary row and the other rotating row. A rotating blade of air, also known as a rotor, accelerates the liquid. Fixed blades (also called vanes or stators) slow down and redirect the direction of fluid flow, arranging the rotor vanes for the next step.

These compressor types require a large number of components. And also, they have high material quality. Therefore axial compressors are expansive. These types of compressors use in CNG stations and all gas turbines.

Advantages:

- It is very efficient than other types of compressor

- It has a high-pressure ratio

- It is best for multi-staging

Disadvantages:

- It is relative expansive

- It has a difficult manufacturing

- These compressors have high weight

FAQ Section

What is a compressor used for?

A compressor uses to transfer the air or gas from one location to another by increasing the pressure of air or gas through the compression process. The compressors use for different applications such as refrigerants, fertilizer industries, food industries, and submarines, etc.

What is the definition of a compressor?

A compressor is a machine that uses to transfer the fluids from one location to another location by increasing their pressure.

Which compressors are used in AC?

A reciprocating compressor is the most famous type that uses in AC. A piston inside the AC compressor moves forward and backward to suck and compress the air.

What is the function of a compressor in sound?

In a sound system, a compressor uses to reduce the dynamic range by compressing the sound.

In this article, I deeply explain the air compressor and its different types. So, I try my best to explain this topic. If you need any clarification, then please let me know in the comment section. I will try my best to respond to you with the right answer.