General Details:

PVA is produced by Vinyl acetate (VAC) as the raw material. VAC is polymerized into polyvinyl acetate (PVAC) by radical polymerization, and then it’s hydrolyzed fully or partially to produce PVA series products. PVA has good film-forming properties, PVA film has excellent adhesion, solvent resistance, abrasion resistance, tensile strength and gas resistance. Partially hydrolyzed PVA has both hydrophilic and hydrophobic functional groups, so this product has interfacial activity, which can be used as dispersant in polymer emulsification and suspension polymerization. These unique properties make PVA widely used in all fields of life.

| Appearance: | Granule or powder |

| Color: | White or yellowish |

| Water solubility: | Swelling in water at room temperature , completely dissolving in hot water, nonpoisonous and harmless, safe and environment-friendly. |

| Chemical resistance: | Hardly affected by weak acids, weak alkalis, organic solvents (Hhydrocarbons, higher alcohols, ketone, esters), has excellent oil resistance |

| Miscibility: | Be miscible with starch, cellulose derivatives and many surfactants, have good stability (May form separate layers under long-term placement) |

| Film forming: | PVA has good film-forming properties, PVA film has excellent adhesion, solvent resistance, abrasion resistance, tensile strength and gas resistance |

| Type | Hydrolysis (mol/mol,%) |

| 2688 (088-60) | 86.5-89.0 |

Main Applications Include:

| Texitle sizing/printing |

| Film formation |

| Adhesion |

| Paper processing and packaging |

| Building materials |

| Pharma and cosmetic materials |

| Agriculture and forestry |

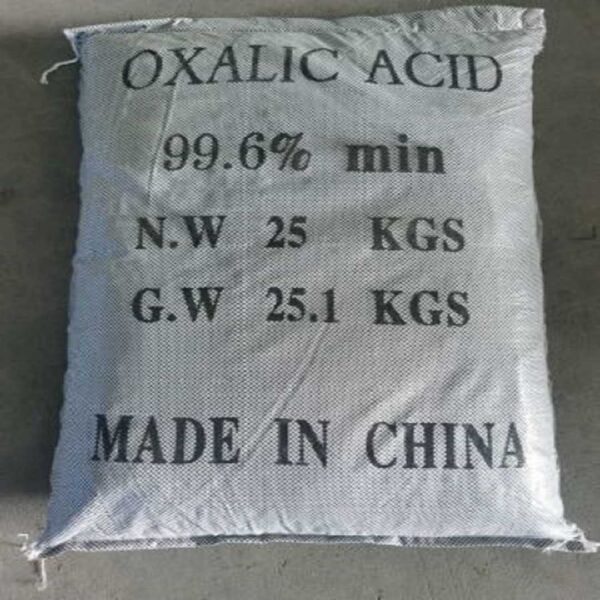

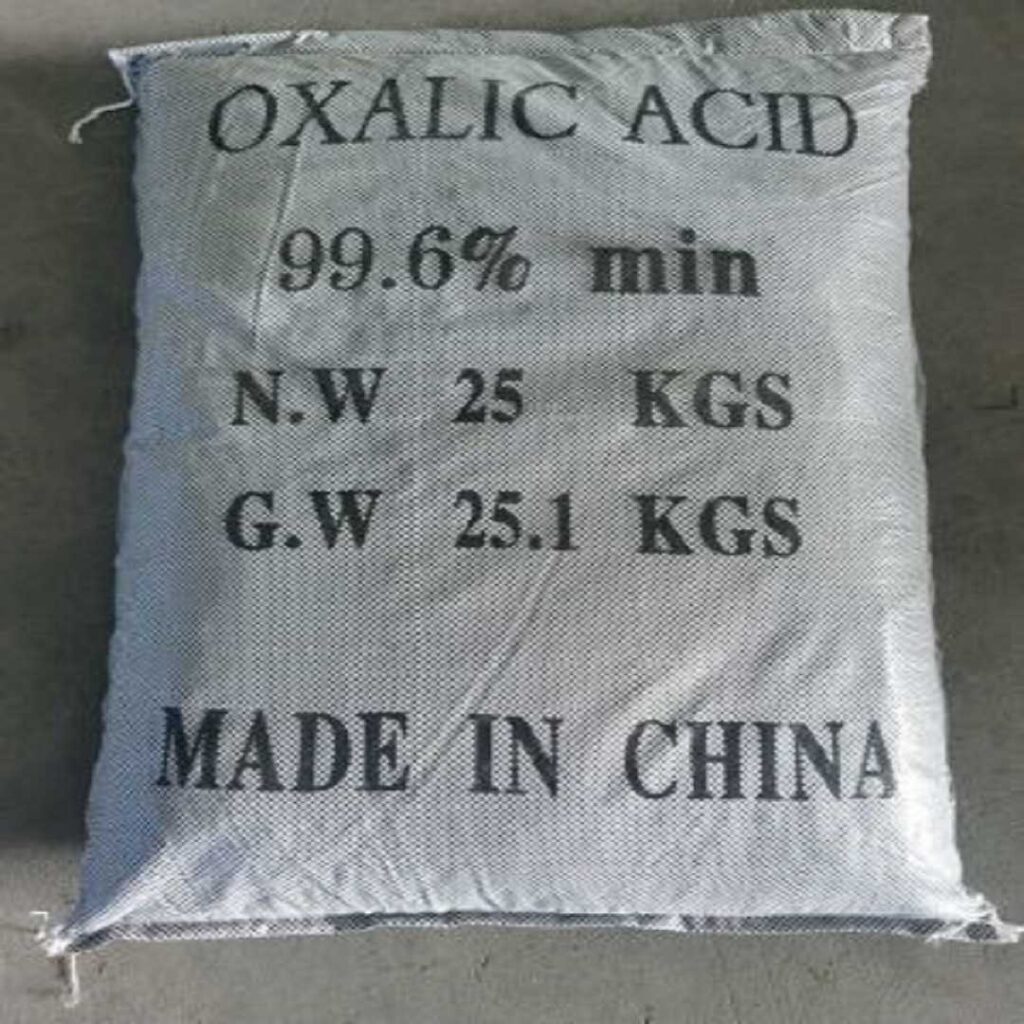

Packing

20kg paper-plastic compound bag