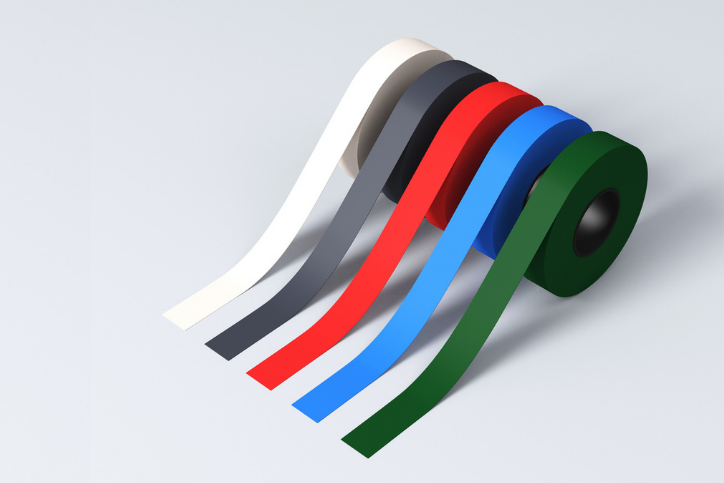

Vinyl Tapes with a rubber adhesive makes an ideal tape for marking lanes, indicating safety hazards and color coding in factories, warehouses, parking lots, joint sealing, pipe wrapping, decorating, and light bundling. Vinyl tape resists wear, weathering and abrasion making for a tough and long-lasting tape. Vinyl Tape is faster and easier than paint for marking lanes and their rubber adhesive sticks on contact. Solid color vinyl tape outlasts paint but removes cleanly without adhesive residue. Our vinyl tape stretches and conforms to contours easily. We provide a wide range of colors and sizes.

There are market 4 distinct varieties of Vinyl Tapes:

- Electrical Tapes

- Pipewrap Tapes

- Vinyl and Electroplating Tapes

- Hazard Stripe Tapes

PipeWrap Tapes

Pipewrap Tapes are moisture resistant, anticorrosive, and are offered in various thicknesses, printed and unprinted.

- Pipewrap tapes are composed of a stabilized, plasticized, PVC film coated with a non-corrosive pressure sensitive adhesive.

- They are moisture resistant and anticorrosive.

- They have outstanding conformability and adhesion to metal and plastic.

Vinyl & Electroplating Tapes

- Vinyl and Electroplating tapes are OSHA-approved vinyl tapes comprised of a stabilized, plasticized PVC film that is coated with a non-corrosive rubber based pressure sensitive adhesive.

- They have excellent resistance to moisture, acids and alkalines, chemicals, oils, abrasion, and weathering.

- They are typically recommended for floor or aisle marking in conformance with OSHA requirements, but they may be used for almost any marking or color-coding application.

Electrical Tapes

Electrical Tapes are manufactured to UL and Mil specifications, general purpose to high performance.

- Can-Do’s electrical tape is value priced and constructed of a plasticized and stabilized soft PVC film.

- It is coated with a rubber-based adhesive on one side.

- The non-corrosive pressure sensitive adhesive requires no heat, moisture, or other preparation and results in an easily applied quality finished product.

- Can-Do also stocks a variety of high performance electrical tapes that meet various MIL and automotive specifications.

Hazard Stripe Tapes

Hazard Stripe Tapes are used to mark hazardous areas with different color code combinations.

- Hazard stripe tapes are used for marking floors, handrails, steps, hazardous areas, and for color-coding, bundling, and identification.

- These PVC tapes may have a glossy overlaminate for appearance and protective purposes.

- They are abrasion resistant and resistant to acids, alkalines, and oils.